This continuous emissions monitoring system (CEMS) monitors the gases produced by the motors at our facilities.

The gas sample is analysed on a wet basis and at a temperature above 180°C (hot-wet) to ensure that it is processed correctly. The established regulations for this type of activity (power generation) and the fuel used (fuel-oil) were taken into consideration when designing the system.

The following parameters are monitored by the CEMS:

• Gases: NO, NO2, SO2, CO.

• Particles.

The installed gas analysis system has NGC1 certification, which is renewed every six months. In addition, a second filter wheel was included in the system to check the calibration of each parameter, preventing the use of span gas bottles for these checks.

This system became necessary following a change in regulations. In April 2019, new regulations were published by the Ministry of Environmental Affairs and Natural Resources of the Dominican Republic on controlling air pollutant emissions from fixed sources, replacing the regulations previously in effect. A deadline of 30 December 2021 was set to adapt to the new regulations.

The new regulations seek to lower the limits applicable to air emissions and better control them by permanently monitoring emissions from fixed sources in the following activities: cremation furnaces, incinerators, thermal power plants that use coal and bunker fuel, asphalt, cement factories and biomass and bunker fuel boilers. In short, this monitoring will improve the control of pollutant emissions.

The CEMS was installed in one of the stacks at each power plant in the country: Palamara and La Vega. These two power plants are the first in the country to have been adapted to the new technical environmental regulations. It is important to note that they are also the only ones based on this technology where continuous monitoring systems have been installed.

The project was implemented in various stages. Firstly, a contract was awarded to INERCO (a recognised and certified company in Europe) for the supply and start-up of emissions control equipment that meets international regulations. This company is certified under UNE and USEPA standards.

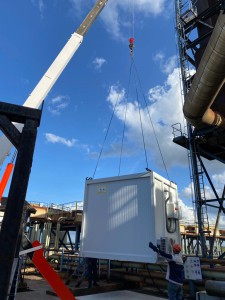

The CEMS components were then installed by local companies under the direct supervision of staff from GPG República Dominicana and INERCO, who ensured that the controls required by the manufacturers were applied during installation.

GPG is proud to have met this milestone that allows us to better control the pollutant emissions produced at our facilities, thus strengthening our commitment to care for and protect our environment.